VariStroke is Woodward’s line of linear electro-hydraulic valve actuators for operation of steam or hydro turbine control valves. They ensure the well functioning of the steam turbine , hydraulic turbine control or control valves in general. These linear actuators use a low pressure oil supply to generate an output force from the cylinder.

Thanks to its precision and high positioning resolution, it is ideal for direct control of steam turbine valves, including turbine speed and load. Its electronic module accepts one or two 4 – 20 mA position request signals (redundant) to position the valve control, as well as two redundant position feedbacks.

Features and benefits

- Dirt tolerant design

- Two moving parts

- 50 lbf chip shear force

- Self-cleaning valve design

- Integrated driver

- Two 4-20 mA demand inputs

- Included valve flow linearization table

- Side-load tolerant

- Shaft bearings

- Triple seal technology

- Precise position control

- Redundant MLDT position sensors

- Certified for hazardous locations

- High calibration capacity (from 50 to 100% of the nominal stroke)

- Speed response to significant load variations to avoid overspeed

- Hydraulic supply pressure from 5 to 35 bars

- Improve valve seal life thanks to controlled closing

- Increased reliability: power supply, control signal, position measurement redodants

- Self-tuning of the servo PID

- Fast slew rates/times

- Application dependant

- Slew rate up to 762 mm/s

Financial benefits:

- No special filtration required

- No need for dedicated oil center (use of the machine’s lubrification circuit)

- Cost reduction of a non-integrated servo distributor system

- Cost reduction of a non-integrated pilot system

- Reduction of engineering costs with a fully integrated system

- Reduction in storage costs for various square parts (filters, oil pumps, pilot valves, position feedback, servo-distributor, etc…).

- Reduction of installation costs

- Reduction of testing and commissioning costs

- Reduction of maintenance costs

- Reduction of turbine trips linked to polluted oils

- Reduction of turbine trips linked to significant load variations

- Energy saving on the supply of an auxiliary oil plant and its refrigeration

- 3 years warranty Wooward equipement

Modernization

Affected systems:

Any hydraulic control system of inlet valves can be replaced by our VariStroke systems, whether it is an ATEX zone or not.

Allows the elimination of a speed oil plant, the linkages between the various control and hydraulic power systems.

The investment is quickly paid for the system’s reliability (reduction of tripping) and the cost of maintenance.

Exemple de réalisation :

Associated equipment

QuickTrip is an electro-hydraulic trip unit, IEC61508 certified, designed for use in steam turbine shutdown systems for fast and relibale discharge from the turbine trip oil manifold.

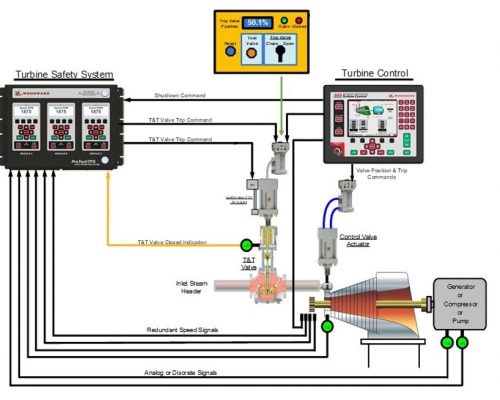

The 505 D governor is designed to work with industrial steam turbines of all sizes and applications. This steam turbine controller includes algorithms and logic specifically designed to start, stop, control, and protect industrial steam turbines, compressors, pumps or industrial fans.

The 505XT controller is designed to operate with a single valve, or a single industrial exhaust / intake steam turbine of all sizes and applications. This steam tubrine governor includes algorithms specially designed to start, stop, control and protect industrial steam turbines, or turbo-expanders drive generators, compressors, pumps or industrial fans.

The Flex500 control system represents a new generation of turbine and engine control. This controller is an industrial hardware platform that provides rugged, inexpensive control for a wide variety of turbine, motor, and compressor applications.

Woodward ProTech-GII / TPS / MSM products are designed to safely shut down any steam, gas, hydraulic equipment, engine or turbine upon detection of a safety problem.