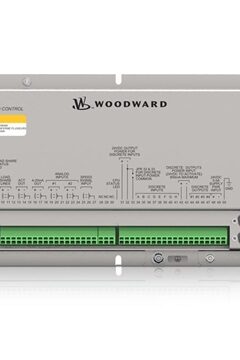

The Peak200 Woodward control is available in a wall-mounted version designed to be mounted on a wall or skid near the turbine, or in a flush-mount version designed to be installed in a panel or standard cabinet door. The product is designed to meet NEMA 4x corrosion resistance tests and has an IP56 rating, protecting it from dust and water jets.

The front panel of the control serves as both a programming station and an Operator Control Panel (OCP). This user-friendly front panel allows engineers to access and program the unit according to the specific needs of the plant, while operators can easily start/stop the turbine and activate/deactivate any control mode.

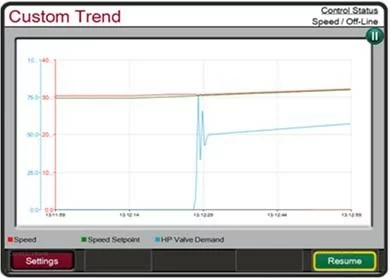

Password protection is used to safeguard all settings in the device’s programming mode. The controller’s 5″ graphic display allows operators to view both actual and setpoint values on the same screen, simplifying turbine operation.

Wiring

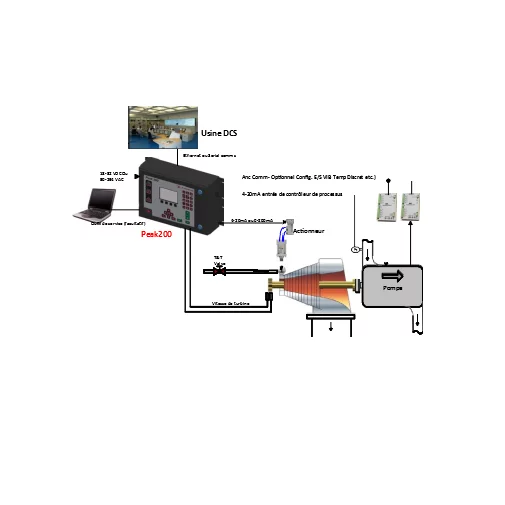

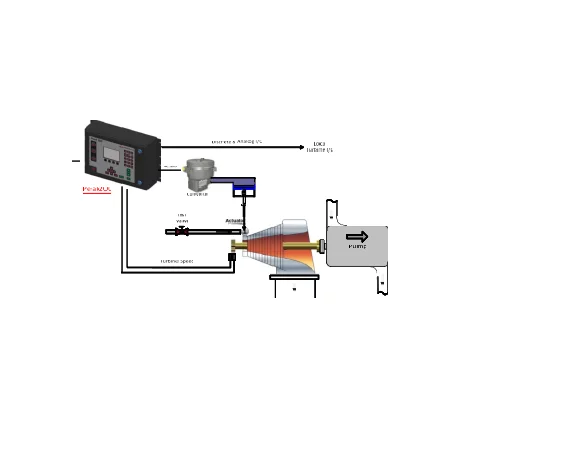

Access to the turbine interface input and output wiring is located on the lower rear panel of the controller. Removable terminal blocks facilitate installation, troubleshooting, and system replacement. Optionally, users can increase the number of input and output signals to/from the Peak200 control by connecting LinkNet-HT distributed I/O nodes to the controller’s CAN communication ports and configuring the Peak200 Woodward control to use the connected distributed inputs and outputs. The following additional I/O signals can be connected to the Peak200 control via CAN communications:

– (8) 4-20 mA input channels and (2) 4-20 mA output channels (via 1 LinkNet-HT AIO module)

– (8) RTD signals (via 1 LinkNet-HT RTD module)

– (16) Digital inputs (via 1 LinkNet-HT DI module)

– (16) Relay output drivers (via 1 LinkNet-HT oxygen measurement module)

Designed for steam turbine control, the Peak200 control includes two PID controllers (Speed & Cascade), several startup routines (manual, automatic, remote), and multiple protection functions (overspeed, critical speed range, etc.) that can be configured by a user according to the specific application requirements. Users can configure the various Peak200 PID controllers, startup routines, and protection levels themselves without needing a specialized control engineer. Once configured, the Peak200 performs a configuration check to ensure that the programmer has not made any basic configuration errors.

RemoteView

Optionally, users can utilize Woodward’s RemoteView software with the Peak200 to function as a remote control panel and/or engineering station. Once installed on a remote computer or touchscreen, this software provides the following additional features:

– Perform the same display functions of the Peak200 front panel (monitoring, control, adjustment, and configuration) on the corresponding computer or touchscreen.

– Full free functionality for 2 hours.

– Licensed for continuous graphical interface operation.

– Password-protected login security is used to manage RemoteView application functions.

Refer to Woodward Product Specification B03424 for more information.

The Peak200 includes a suite of service tools allowing users to perform the following functions:

– Download configuration files from the Peak200 for backup onto another device.

– Upload configuration parameter files to the Peak200.

– View real-time or saved trend files.

Additional Features:

– Field configurable

– Integrated graphical control panel

– Ease of installation, configuration, and use

– Built-in first-out fault indicator

– Trip and alarm event recorder

– Internal turbine simulator

– Adaptive PID controller

– Real-time clock synchronization via SNTP

– Ethernet and serial communications

– Same form-fit function as the previous Peak150 controller

– Available in wall-mount and flush-mount versions

– Sulfur-resistant conformal coating

– Certified for hazardous locations.