Introduction

Precise control of the rotational speed of a motor or turbine is essential to guarantee the reliability, performance and safety of industrial installations. Woodward, a world leader in energy regulation and control, designs speed governors renowned for their robustness and precision. Understanding how Woodward speed governors work enables you to better control their use, optimize the performance of rotating machines and prevent failures.

Operating principle woodward governors

The operation of a Woodward speed controller is based on a real-time control loop. This loop begins by measuring the actual speed of the motor shaft using a speed sensor, often magnetic, positioned on the machine. This sensor sends an electrical signal corresponding to the measured speed. The controller then compares this actual speed with a predefined setpoint. The difference between these two values generates what is known as a control error. This error is analyzed by the controller, which then calculates a control signal to correct the speed.

This command signal is transmitted to an actuator, such as a servomotor or control valve, which adjusts the flow of energy supplied to the machine (e.g. fuel, steam or air). In this way, the speed is continuously regulated to remain as close as possible to the set point, even in the event of sudden load variations. This regulation is automatic, fast and constant, ensuring optimum dynamic stability.

Woodward control technologies

Woodward controllers are available in several technological forms, adapted to the specific needs of industrial plants. Mechanical-hydraulic models operate without electronics, using only mechanical forces and fluids for control. They are particularly suited to explosive environments or robust installations where electronics are outlawed.

Electronic controllers, on the other hand, use analog or digital circuits to improve precision and facilitate adjustment. Digital models, such as easYgen or ProAct, offer a highly advanced level of control, incorporating diagnostic functions, remote communication and synchronization with other systems. They can manage multiple energy sources, integrate into complex architectures and be configured via software interfaces.

Industrial applications

Woodward speed governors can be found in many industrial sectors. They can be found on diesel engines, steam turbines, compressors, generators and renewable energy installations. They are used in power plants, heavy industrial sites, marine installations and oil and gas infrastructures. They play a crucial role in keeping rotating machines running smoothly, maintaining constant speed, optimizing energy consumption and protecting mechanical equipment against overloads and instabilities.

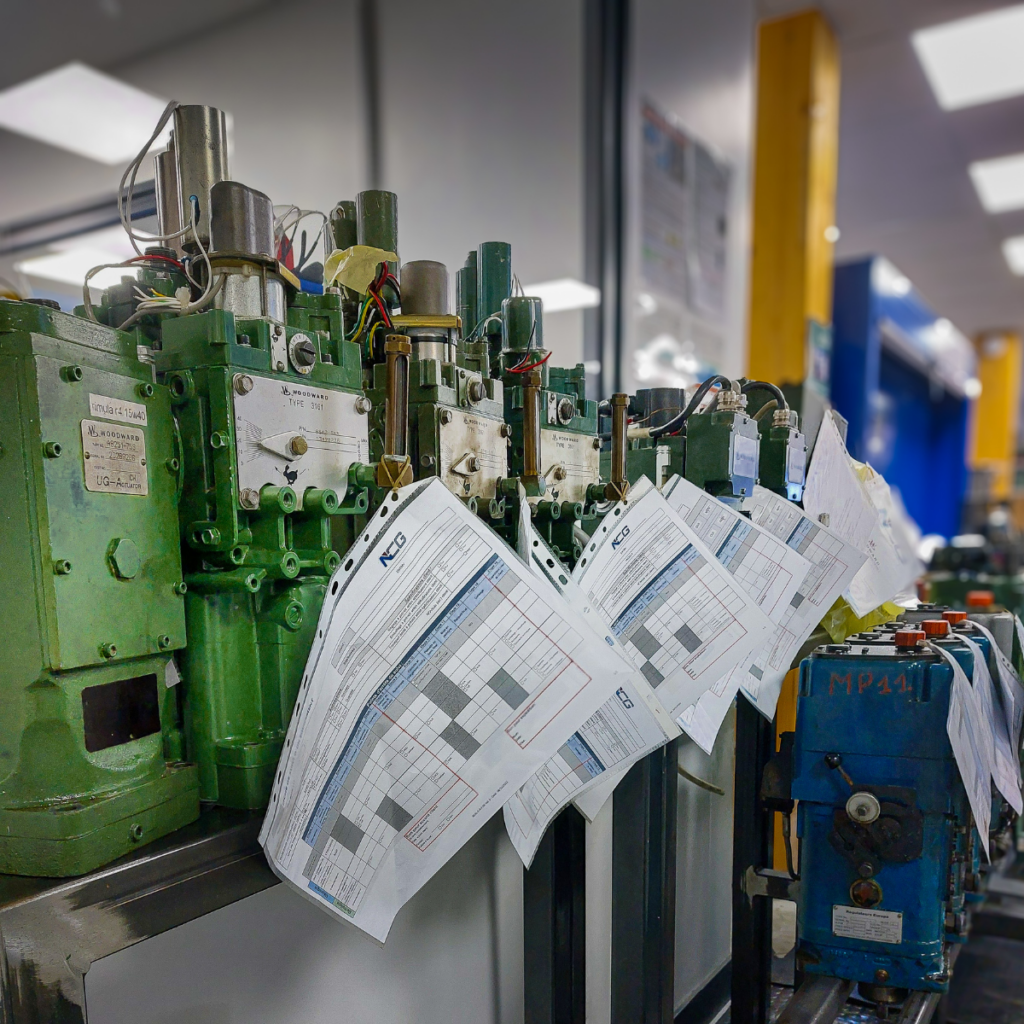

Normandy Control Group's expertise

Official Woodward distributor in France and French-speaking Africa, Normandy Control Group offers comprehensive support for speed governors. The company provides technical analysis of requirements, supply of original equipment, workshop overhaul, reconditioning, on-site installation, commissioning and technician training. Normandy Control Group draws on its experience and know-how in the field to work on complex installations in strategic industrial sectors, notably in Algeria, Morocco, Tunisia, Côte d’Ivoire and Senegal.

Why do call on Normandy Control group/NCG ?

When you choose Normandy Control Group, you choose a partner you can trust for the maintenance and repair of your industrial equipment. As an official Woodward and Parker Meggitt (vibro-meter) distributor in France and French-speaking Africa, including Algeria, Tunisia and Morocco, we offer recognized expertise in the field. We also have two workshops in France, in Le Havre and Marseille, as well as workshops in Côte d’Ivoire and Senegal.