VIBRANT TABLE MODERNIZATION - Meggitt VM600 MKII

Customer problems

The customer needed to instrument its equipment to guarantee the reliability and quality of its production tools. Normandy Control Group stepped in to solve the problem.

Constraint : Explosive atmosphere

– Compliance with ATEX standards and equipment.

The objectives were to

- Increase reliability

- Increase availability

- Increase maintainability

- Better monitoring of operation

Solutions

Equipment installed :

Sensors: 12x CA280

Conditioner and galvanic barrier: 12x IPC 707, 12x GSI127

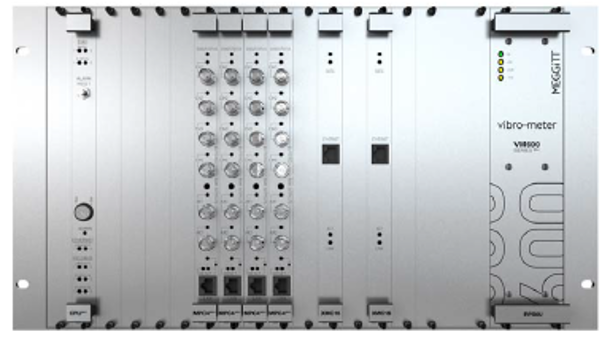

Vibration rack: 1x Meggitt VM600MK2

results

The customer can now monitor all vibration data from his vibration table. Vibration levels on the vibrating table are adjusted to optimize the manufacturing process.

Why call on Normandy Control Group/NCG?

When you choose Normandy Control Group, you choose a partner you can trust for the maintenance and repair of your industrial equipment. As an official Woodward and Parker Meggitt (vibro-meter) distributor in France and French-speaking Africa, including Algeria, Tunisia and Morocco, we offer recognized expertise in the field. We also have two workshops in France, in Le Havre and Marseille, as well as Woodward workshops in Côte d’Ivoire and Senegal.