Ensure the reliability of industrial equipment with Parker Meggitt's VM600

In industrial environments, vibration monitoring is an essential lever for ensuring equipment reliability, safety and longevity.

Rotating machines, such as turbo-alternators, play a strategic role in many sectors, including energy, aeronautics and heavy industry. To ensure their smooth operation, advanced monitoring systems are essential.

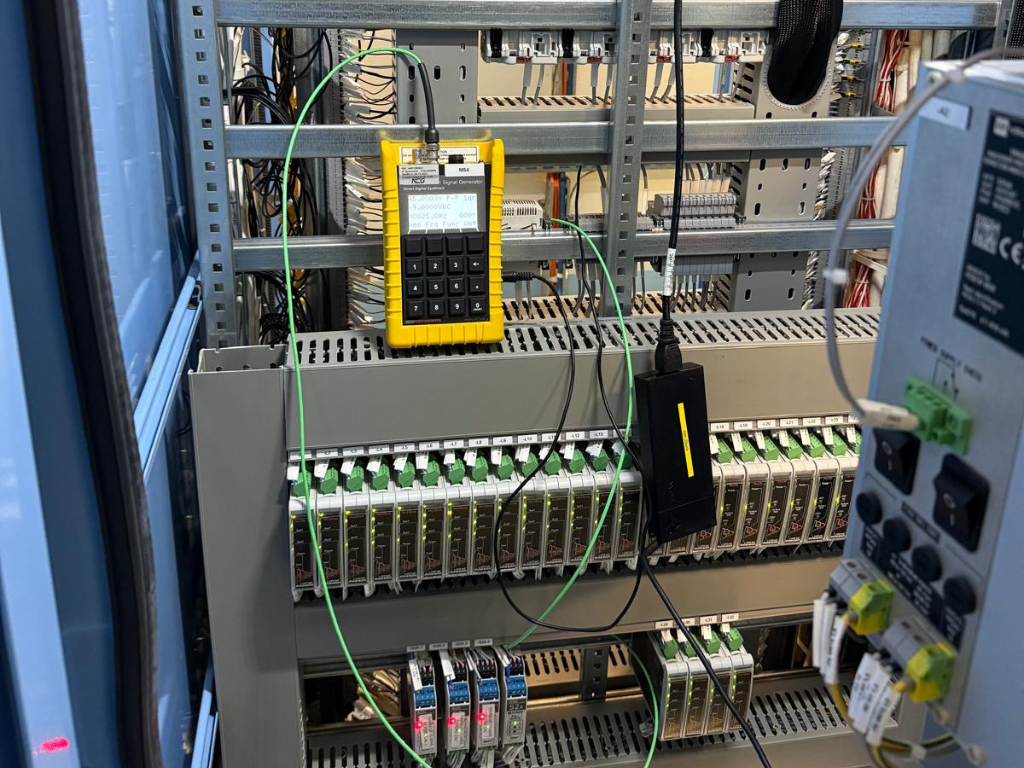

With this in mind, Normandy Control Group’s experts recently worked on a strategic turbo-generator set to test and validate Parker Meggitt’s VM600 vibration protection racks. This intervention confirmed the effectiveness of this technology in detecting and preventing possible anomalies.

Why is vibration monitoring essential?

Rotating machines are subject to constant vibration which, if left unchecked, can lead to :

- Premature wear of components

- Increased maintenance costs

- Unplanned breakdowns that can impact production

- Increased risks to plant and personnel safety

Thanks to real-time vibration monitoring systems, even the slightest abnormal variations can be detected and prompt action taken before a problem becomes critical.

What is the VM600 from Parker Meggitt?

The Meggitt VM600 is an advanced vibration monitoring and protection system for rotating machinery. It has been designed to offer :

- Real-time detection of vibration anomalies

- An advanced warning system for rapid intervention

- Optimized maintenance to avoid production stoppages

- Enhanced industrial plant safety

This type of technology is particularly well suited to turbines, turbo-alternators, compressors and other critical industrial equipment.

A key intervention to guarantee plant safety

During this intervention, our specialists carried out a series of in-depth tests to validate the functionalities of the VM600 rack. The aim was to ensure that the system offered optimum protection for equipment, guaranteeing its reliability and performance.

In particular, our teams :

- Verified vibration sensor signals

- Tested alarm and automatic shutdown thresholds

- Confirmed correct operation of protection modules

- Ensured system integration with existing architecture

This expertise gives operators a precise view of the state of their equipment, and enables them to anticipate potential malfunctions.

Why do call on Normandy Control Group/NCG ?

When you choose Normandy Control Group, you choose a partner you can trust for the maintenance and repair of your industrial equipment. As an official Woodward and Parker Meggitt (vibro-meter) distributor in France and French-speaking Africa, including Algeria, Tunisia and Morocco, we offer recognized expertise in the field. We also have two workshops in France, in Le Havre and Marseille, as well as workshops in Côte d’Ivoire and Senegal.