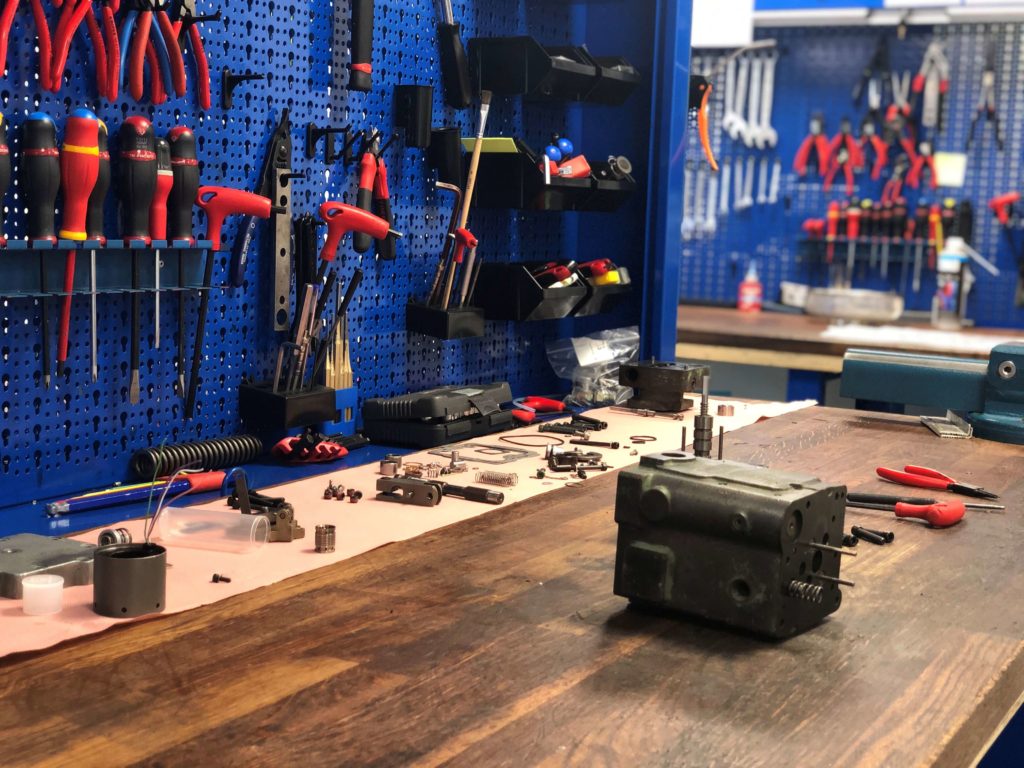

The importance of preventive equipment maintenance

Preventive maintenance is crucial to the long-term reliability and performance of industrial equipment. At Normandy Control Group, we understand the importance of regular maintenance to avoid unexpected breakdowns, extend the life of your machines and optimize your company’s productivity.

Extending equipment service life

By carrying out regular inspections and minor repairs before they become critical, preventive maintenance keeps your equipment in excellent working order. This helps you avoid premature deterioration and extend their service life, reducing the need for frequent investment in new equipment.

Reduce repair costs

Unexpected breakdowns can lead to high costs, not only in terms of equipment repairs, but also due to production downtime. With well-planned preventive maintenance, you can identify and correct potential problems before they become more serious and costly. This results in considerable savings over the long term by avoiding the unexpected costs associated with urgent repairs.

Improving safety and reliability

Unexpected breakdowns can also lead to safety risks for employees and disrupt production. By keeping your equipment in good condition, you reduce the risk of accidents due to technical faults and ensure a safer working environment. A well-maintained machine is also more reliable, enhancing production continuity.

Optimizing productivity

Preventive maintenance minimizes production downtime caused by technical faults. With equipment running at optimum efficiency, your production processes are more effective and less prone to unplanned downtime. This improves not only productivity, but also work and product quality.

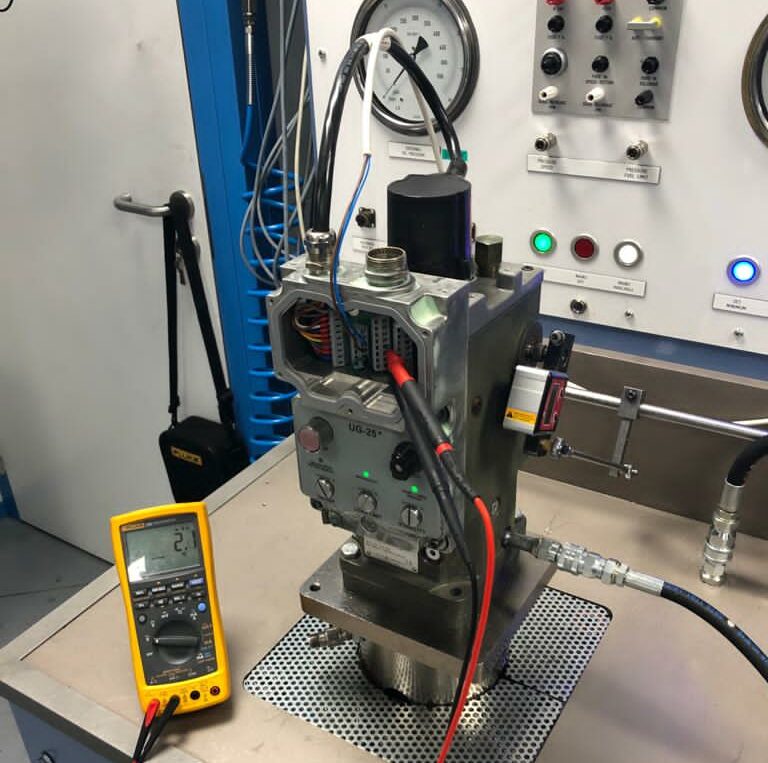

Why call on Normandy Control Group?

When you choose Normandy Control Group, you choose a partner you can trust for the maintenance and repair of your industrial equipment. As an official Woodward and Parker Meggitt (vibro-meter) distributor in France and French-speaking Africa, including Algeria, Tunisia and Morocco, we offer recognized expertise in the field. We also have two workshops in France, in Le Havre and Marseille, as well as workshops in Côte d’Ivoire and Senegal.