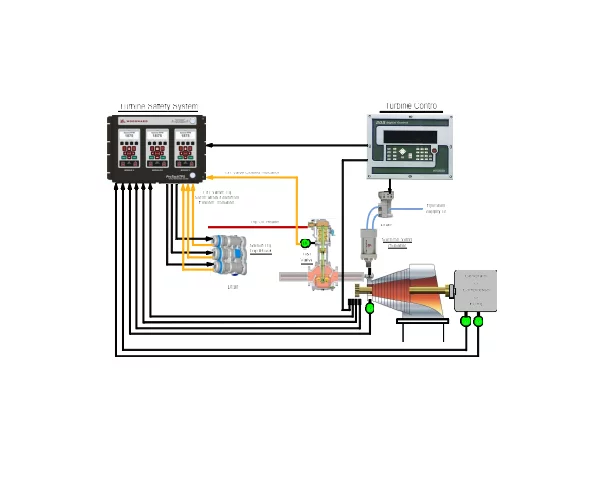

The 2-out-of-3 design of this trip block, QuickTrip Woodward, provides users with a high level of system reliability and compliance with industry standards such as API-670, API-612, and API-611.

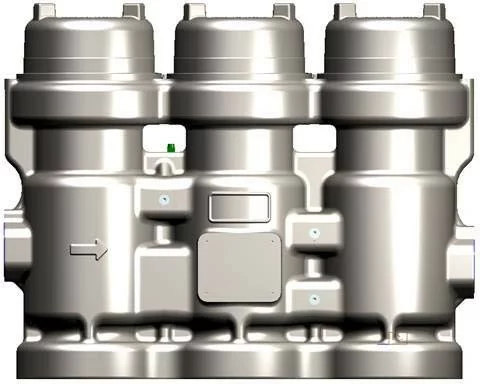

This trip block is housed in a fully integrated assembly that includes three patented, dirt-tolerant rotary trip valves. These valves are connected to allow two-out-of-three voting to ensure that a component failure (valve control, valve, wiring, connector, etc.) does not result in an unintended trip. The modular design of the QuickTrip also allows users to replace critical components while the turbine is in operation.

Designed to quickly and reliably purge the trip oil manifold pressure, at least two of the three QuickTrip solenoid valves must be de-energized to open a purge path from the trip oil manifold to the system drain.

The QuickTrip Woodward accepts one or two 24 VDC power sources (redundant) to power each solenoid, and uses three independent discrete stop commands from a safety logic solver, such as the Woodward ProTechTPS (independent voting models), to test and control each solenoid valve.

As steam turbines are often used in hazardous locations where flammable gases may be present, the QuickTrip is designed to be mounted next to the steam turbine and is certified for use in Zone 1 or 2 hazardous areas (Class 1 or Class 2).

When paired with a Woodward ProTech TPS safety logic solver, the ProTech TPS performs routine safety system diagnostics, ensuring the unit’s functionality while the turbine is online, and monitors response times to ensure the turbine can be safely shut down in an emergency.

The total installation cost of this fully integrated trip block is low, as it is pre-assembled and factory-tested, significantly reducing manufacturing, installation, and testing time for OEMs and end-users.

Dirt-tolerant design:

– No clogging orifices

– 25 lb chip-shearing force

– Self-cleaning valve design

Fast trip time:

– < 50 ms solenoid action

Increased reliability:

– 2-out-of-3 voting design

– Online repairable

– No single point of failure

– Testable online

Safety certified for use in IEC61508 SIL-3 systems:

– API-670 compliant

Local and remote position indications:

– Local LEDs

– Remote relays

Compact size

Certified for hazardous locations:

– CSA Class I, Div. 1 & 2

– ATEX Zone 1 & 2

– IECEx Zone 1 & 2