How do speed control systems improve energy efficiency?

At a time when reducing energy costs and minimizing carbon footprints are key industrial concerns, speed control systems are an essential solution. Widely used in sectors as diverse as energy, transport and manufacturing, these devices enable optimum management of energy resources while extending equipment life.

Here’s how these devices help improve energy efficiency.

What is a cruise control system?

A speed regulation system is a device that automatically adjusts the speed of a motor according to the load required. These systems, often based on advanced technologies such as variable frequency drives, help to reduce energy wastage by adapting consumption to actual requirements.

Energy efficiency benefits

Optimizing energy consumption

Conventional motors often run at full power, irrespective of demand. Control systems adjust power as required, avoiding unnecessary expenditure.

Reduced losses

By limiting sudden starts and untimely speed variations, these systems reduce inertia and heat losses.

Longer equipment service life

Proper use reduces wear and tear on mechanical components, cutting maintenance costs and extending plant life.

Compliance with environmental standards

By reducing energy consumption, control systems help to limit greenhouse gas emissions, helping companies to comply with environmental regulations.

Concrete applications in industry

Speed control systems are used in a number of areas:

- Power generation: By adapting the speed of turbines or generators, they optimize production and minimize losses.

- Manufacturing: Variable speed drives enable precise management of production lines, reducing unnecessary consumption.

- Transport: In rail or marine systems, these devices improve motor efficiency by adjusting their operation in real time.

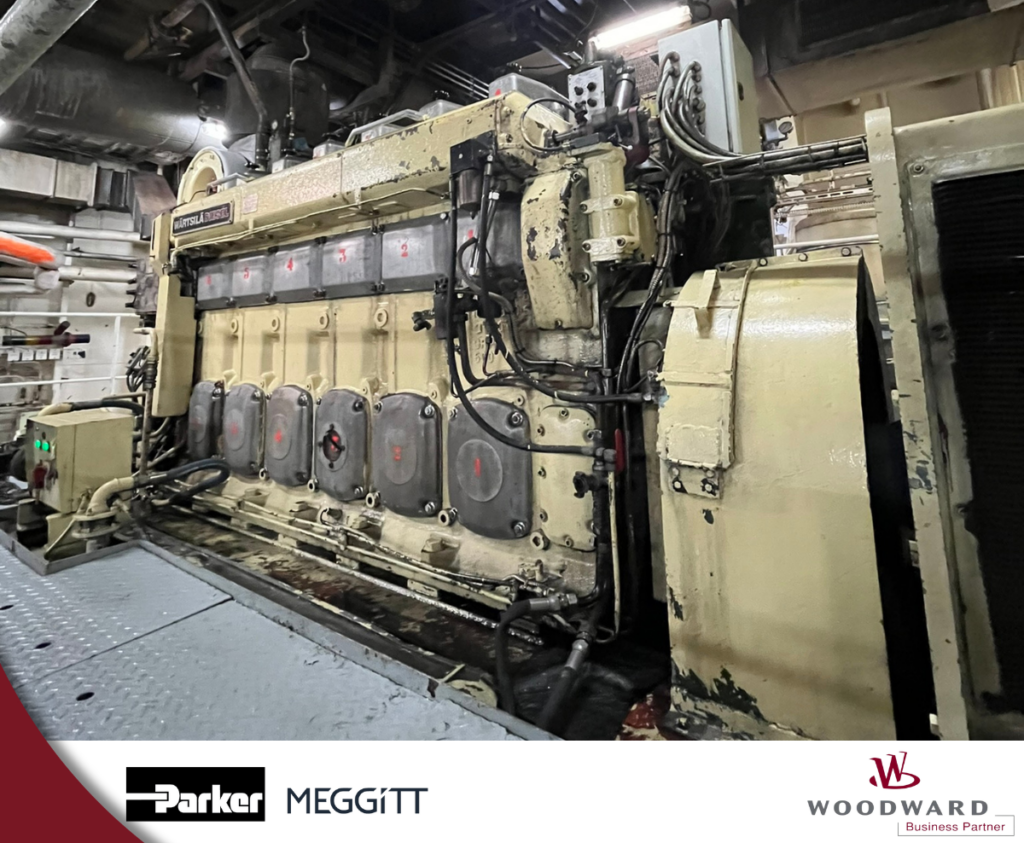

Woodward: a world reference in control systems

Woodward is a world leader in regulation and control systems for motors and turbines. With expertise accumulated over more than a century, Woodward offers innovative solutions that not only reduce energy costs, but also ensure optimum equipment performance. Woodward products are designed to meet the requirements of the most critical industries, guaranteeing superior reliability and efficiency. As an official Woodward distributor, Normandy Control Group offers a wide range of Woodward equipment, as well as equipment overhaul, service and training.

Why call on Normandy Control Group/NCG?

When you choose Normandy Control Group, you choose a partner you can trust for the maintenance and repair of your industrial equipment. As an official Woodward and Parker Meggitt (vibro-meter) distributor in France and French-speaking Africa, including Algeria, Tunisia and Morocco, we offer recognized expertise in the field. We also have two workshops in France, in Le Havre and Marseille, as well as workshops in Côte d’Ivoire and Senegal.