Advanced monitoring to optimize equipment reliability

Normandy Control Group recently participated in the integration of a Meggitt VM600MK2 vibration monitoring rack on a 440MW gas turbine. This installation enables precise monitoring of the machine’s condition and early detection of anomalies, essential for optimizing maintenance and guaranteeing continuity of operation.

In a demanding industrial environment, vibration monitoring plays a key role in anticipating breakdowns and avoiding unscheduled shutdowns. The use of an advanced system like the VM600MK2, coupled with VibroSight software, enables in-depth analysis of equipment dynamic behavior.

The VM600: a system for machine protection

Meggitt’s VM600MK2 is a vibration monitoring and protection system designed for high-power rotating machines such as turbines, compressors and alternators. This modular rack collects and analyzes vibration signals in real time to :

- Continuously monitor the condition of bearings and rotating elements

- Early detection of imbalances, misalignments or mechanical play

- Avoid critical failures by generating alerts adapted to operating conditions

- Easy integration with control systems thanks to flexible interfaces

VibroSight: a powerful tool for analysis and diagnosis

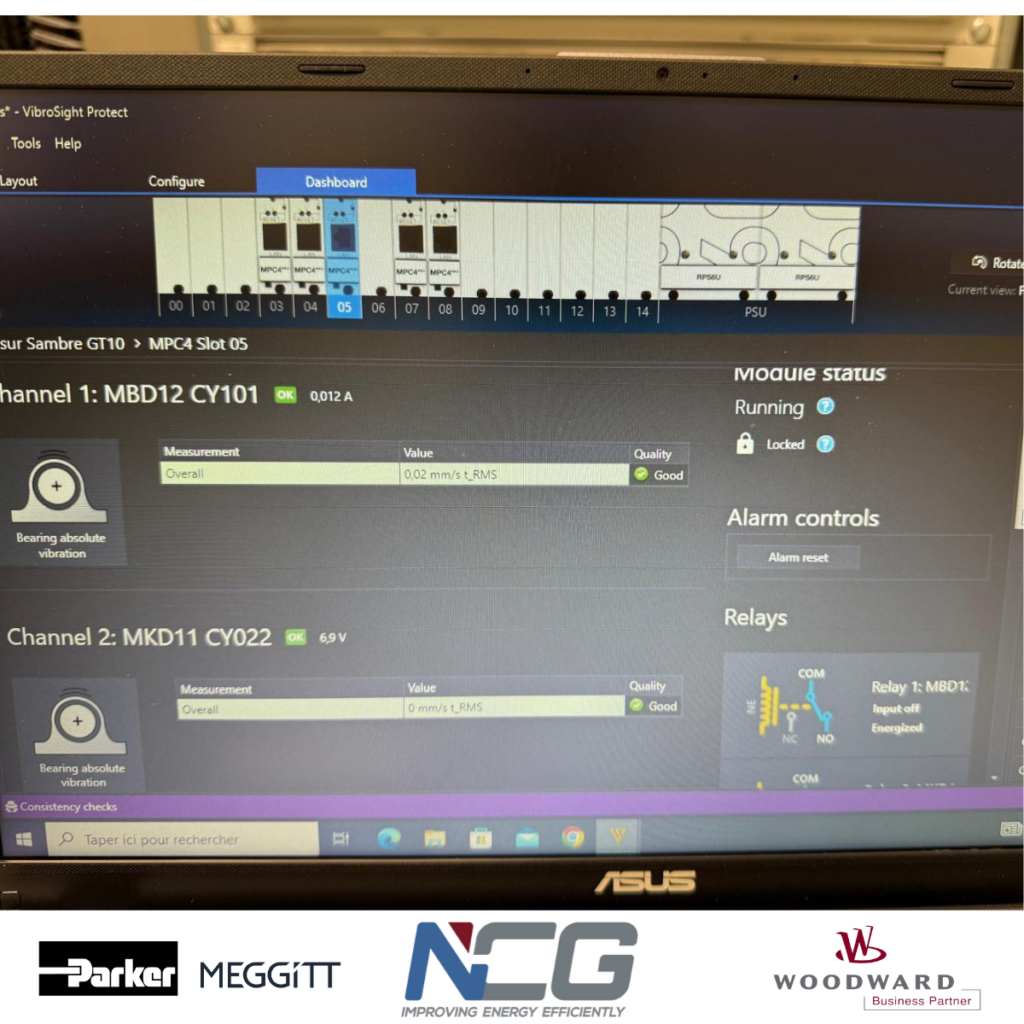

For this installation, VibroSight, Meggitt’s dedicated software, was used to configure and analyze the vibration data.

A true advanced diagnostics platform, VibroSight enables :

- Acquire and process vibration sensor signals in real time

- Display evolving trends, making it easier to anticipate mechanical drifts

- Configure customized alarm thresholds for optimum reactivity in the event of anomalies

- Generate precise reports to improve preventive maintenance

Thanks to its intuitive interface and powerful analysis tools, VibroSight gives operators greater control over their equipment and optimizes condition-based maintenance.

NCG team expands

This mission was also an opportunity to welcome Clément Rousselle, our new project technician, who played an active role in testing and commissioning the system. His expertise in instrumentation and vibration monitoring brings real added value to our team.

With this new installation, Normandy Control Group continues to support its customers in improving the reliability and performance of their critical equipment, based on proven technological solutions.

Why do call on Normandy Control Group/NCG ?

When you choose Normandy Control Group, you choose a partner you can trust for the maintenance and repair of your industrial equipment. As an official Woodward and Parker Meggitt (vibro-meter) distributor in France and French-speaking Africa, including Algeria, Tunisia and Morocco, we offer recognized expertise in the field. We also have two workshops in France, in Le Havre and Marseille, as well as Woodward workshops in Côte d’Ivoire and Senegal.