The importance of service continuity in an industrial environment

In the energy and process industries, every minute of turbine downtime translates into significant financial losses. The reliability of control systems, and especially speed controllers, is therefore critical.

At Normandy Control Group, our philosophy is simple: we never leave an installation idle. We recently demonstrated this commitment during an emergency intervention for one of our clients facing a critical failure of their Woodward 505 controller.

Customer case: Intervention for a Woodward 505 regulator failure

When a customer contacted us following a failure of their control equipment, our technical teams deployed a three-step emergency protocol to ensure business continuity.

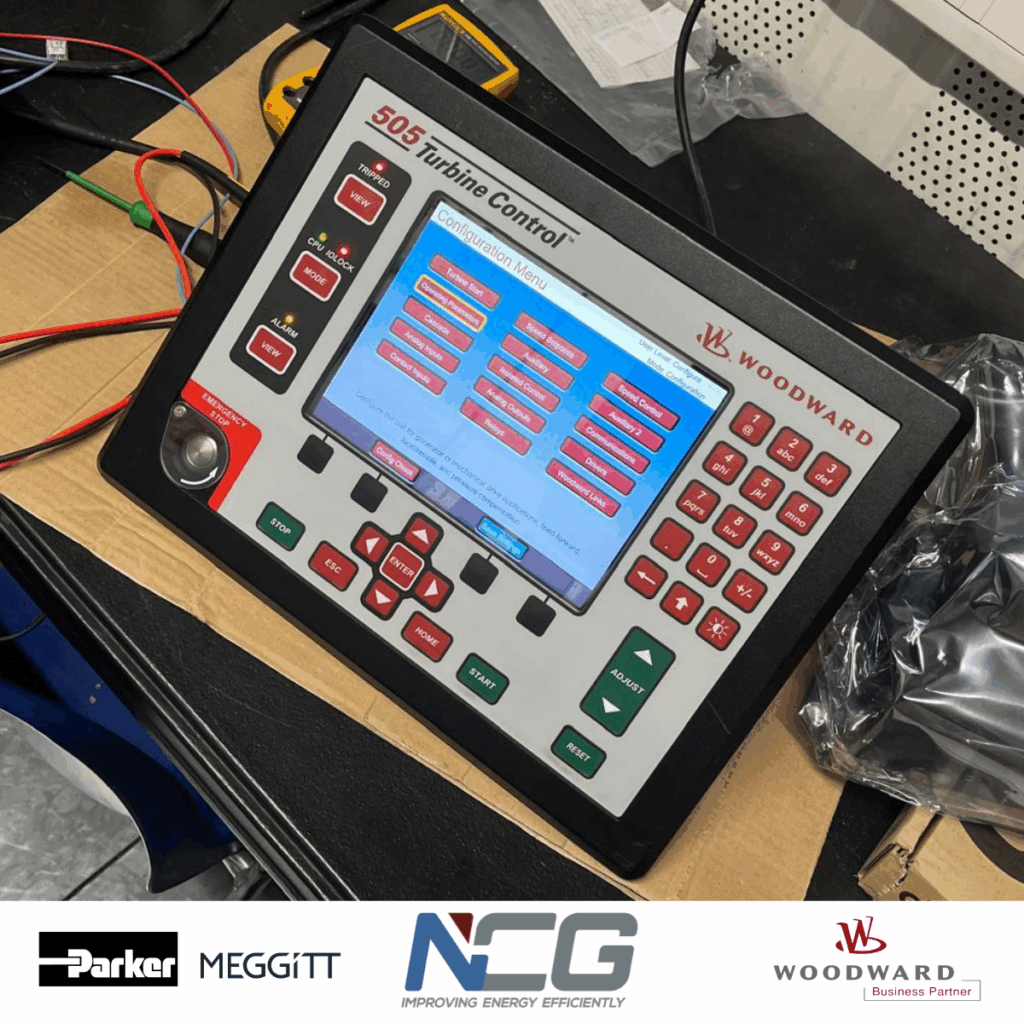

The immediate solution: Installation of loaner equipment

Faced with the emergency, the priority is not just to repair, but to restart. We immediately mobilized our stock to supply and install a loaner Woodward 505.

Repair and return to site

Once the faulty controller was repaired in our specialized workshops, our technicians returned to the customer’s site. This logistical phase is managed entirely by us to simplify the operator’s task.

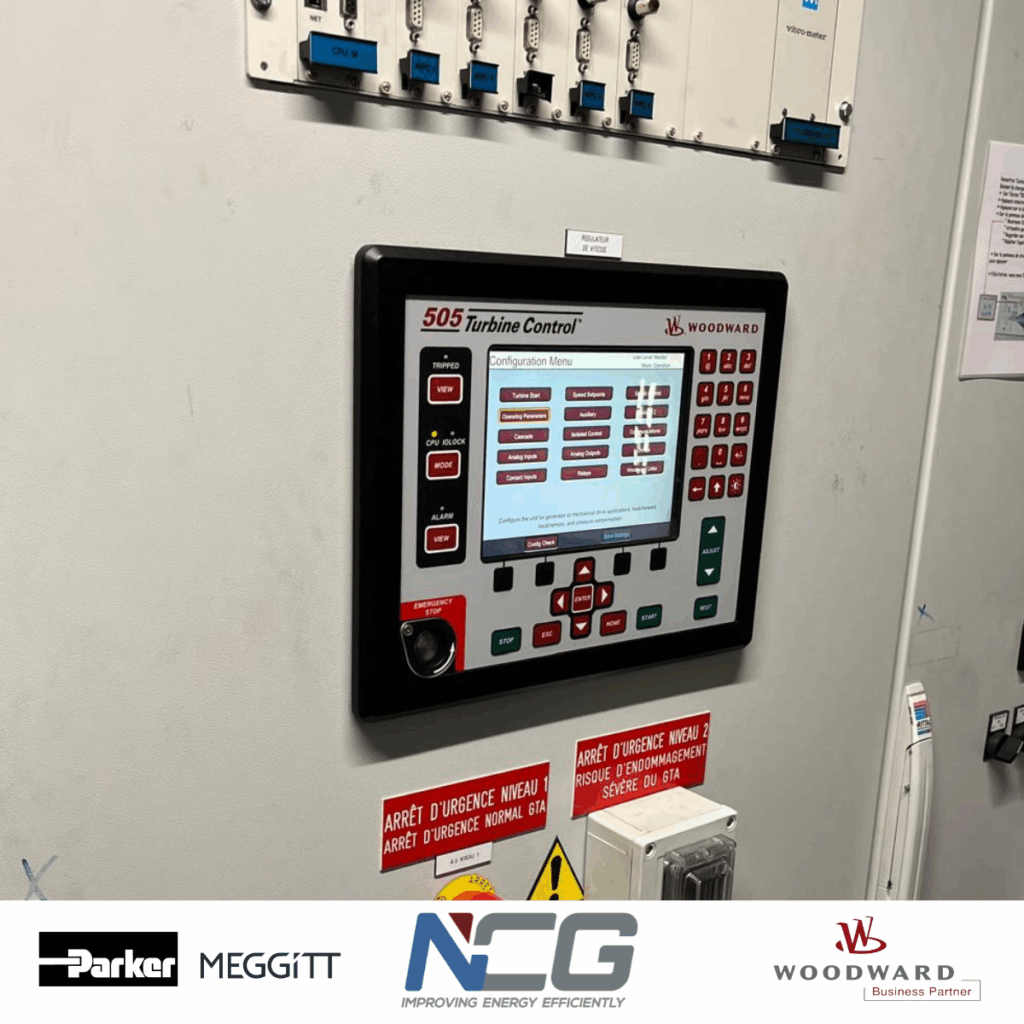

Reinstallation and commissioning

Simply reinstalling the controller is not enough. We carried out:

- The physical reinstallation of the repaired Woodward controller.

- The configuration of the parameters.

- A complete commissioning to ensure that the turbine restarts safely and at optimal performance.

Why do call on Normandy Control Group/NCG ?

Choosing Normandy Control Group means choosing a trusted partner for the maintenance and repair of your industrial equipment. As an official distributor of Woodward and Parker Meggitt (vibro-meter) in France and French-speaking Africa, particularly in Algeria, Tunisia, and Morocco, we offer recognized expertise in the field. We also have two workshops in France, in Le Havre and Marseille, as well as workshops in Ivory Coast and Senegal.