The importance of vibrations in turbine operation

Turbines, whether hydraulic, thermal, or industrial, are subject to significant mechanical stress. Vibration levels are one of the first indicators of their health. Unusual variations can indicate imbalance, alignment issues, or premature component wear. Without proper monitoring, these signals can go unnoticed and lead to costly breakdowns or even the complete shutdown of a facility.

The key role of vibration sensors

Vibration sensors play a fundamental role in turbine protection, enabling precise and continuous measurement of mechanical movements. Placed in strategic areas of the machine, these sensors record vibration variations and transmit the data to a monitoring system. The latter can analyze signals in real time and trigger alerts in the event of an anomaly.

This approach makes it possible to anticipate a failure before it causes an unplanned shutdown. Operators are thus moving from a corrective maintenance approach, which involves intervening only after a breakdown, to predictive maintenance, which involves acting at the right time to avoid costly repairs. In addition to improving facility safety, this method helps optimize operating costs, extend turbine lifespan, and ensure consistent energy efficiency.

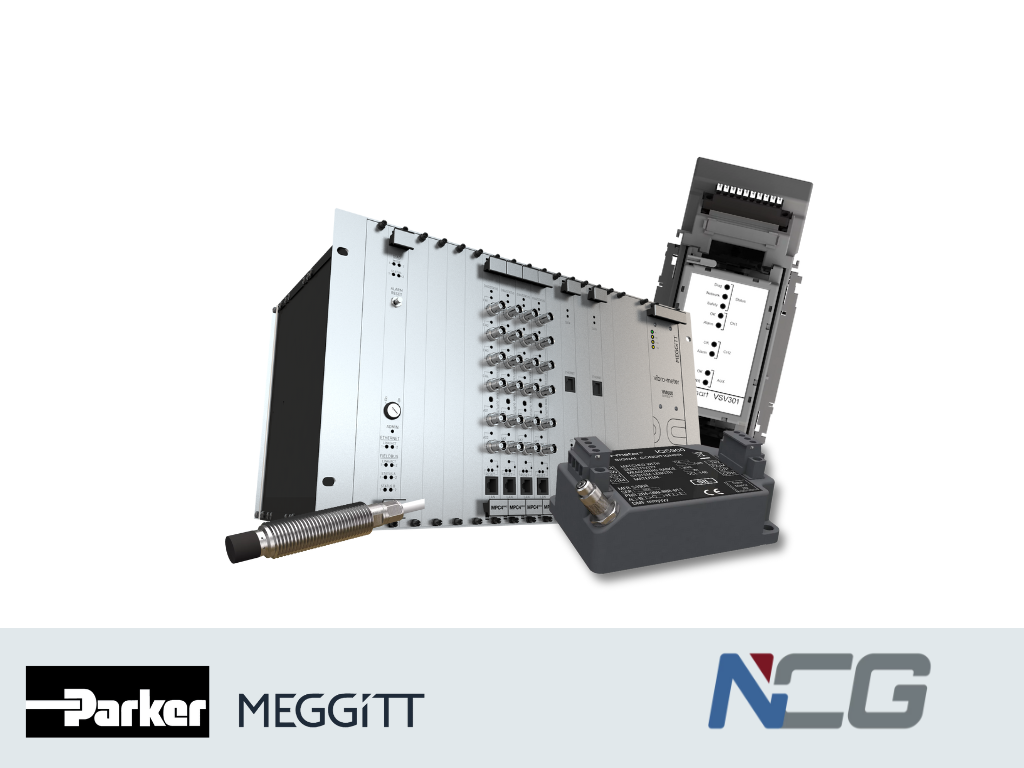

Parker Meggitt solutions distributed by Normandy Control Group

To meet the needs of industrial companies, Normandy Control Group distributes vibration monitoring solutions developed by Parker Meggitt, a globally recognized player for the reliability of its technologies. This equipment includes the SE120 vibration sensors, capable of detecting frequency variations with high precision, as well as the RPV rack, which centralizes and continuously analyzes all collected data.

These systems are already in use on numerous hydraulic turbines in France and offer operators enhanced safety. Their effectiveness is based on early detection of anomalies and a clear monitoring interface, allowing technical teams to make rapid and appropriate decisions. By equipping themselves with such solutions, manufacturers ensure reliable and long-lasting protection, meeting the most demanding industry standards.

Technical and local support

Beyond supplying equipment, Normandy Control Group stands out for its comprehensive support to its customers. For over ten years, the company has been applying its expertise to the regulation and protection of rotating machinery. Its workshops, located in Le Havre, Marseille, Ivory Coast, and Senegal, enable it to respond closely to the needs of operators in France and French-speaking Africa.

Normandy Control Group’s teams handle the installation and commissioning of vibration sensors, as well as their maintenance and calibration. They also provide technical training so that operators and technicians can make the most of the implemented solutions. This personalized support ensures optimal use of the equipment and greater autonomy for teams in the field.

Why do call on Normandy Control Group/NCG ?

By contacting Normandy Control Group, you’re choosing a trusted partner for the maintenance and repair of your industrial equipment. As an official Woodward and Parker Meggitt (vibro-meter) distributor in France and French-speaking Africa, particularly in Algeria, Tunisia, and Morocco, we offer recognized expertise in the field. We also have two workshops in France, in Le Havre and Marseille, as well as workshops in Côte d’Ivoire and Senegal.