Woodward controllers play an essential role in managing the speed and stability of heat engines used in industry, power generation or marine propulsion. Like all control systems, they are subject to wear and technical constraints that can alter their performance over time.

Knowing how to identify the signs of malfunction enables you to anticipate breakdowns, optimize equipment availability and guarantee plant safety. Here are the main symptoms that should alert you to the need for Woodward regulator maintenance.

Signs to watch out for:

1. Speed instability or speed variation

Unstable regulation, with jerking, oscillations or frequent deviations from the speed setpoint, generally indicates a controller malfunction. These anomalies may be the result of worn mechanical components, inappropriate adjustment or internal fouling.

In some cases, the deterioration in dynamic behavior is linked to a loss of sensor accuracy or to electronic parameter drift in digital versions.

2. Abnormal response time

The governor’s role is to rapidly adjust motor speed to load variations. If the system takes longer than usual to stabilize engine speed, this may indicate an internal problem, such as worn moving parts, damaged oil, tired springs or calibration faults.

This symptom may also be the sign of a poorly maintained governor, or one that has been operated beyond its rated capacity.

3. Abnormal noise or vibration

Any unusual noise (rattling, rubbing, grinding) coming from the regulator is a signal not to be overlooked. It could be a mechanical misalignment, a damaged bearing or a loose internal part. These phenomena can precede a sudden breakdown if no action is taken.

In the case of controllers installed on motors subject to strong vibrations, periodic inspection is recommended.

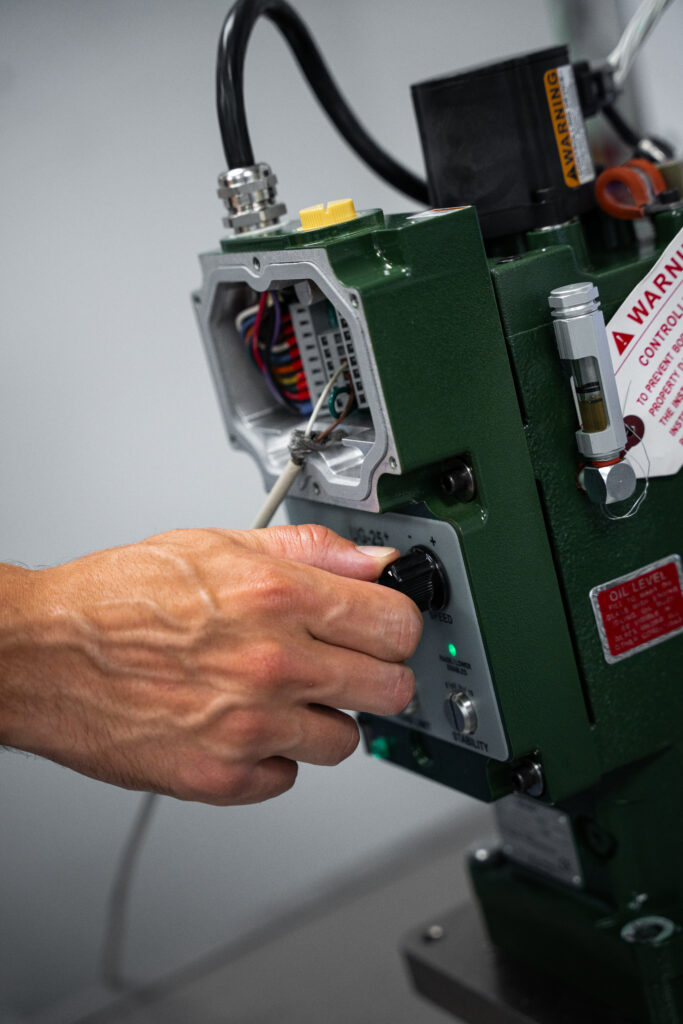

4. Oil leaks or loss of hydraulic pressure

Some Woodward mechanical-hydraulic controllers use oil to ensure the internal movement of components. Any visible leak, however slight, should be taken as a maintenance indicator. A loss of seal can lead to a drop in pressure, irregular operation, or even complete failure.

Used or contaminated oil inside the regulator can also affect system performance.

5. Alarms or system errors on electronic versions

Woodward electronic controllers, such as the 2301D, 505 or 723PLUS, feature advanced diagnostic functions. The recurrent appearance of alarms, fault codes or loss of communication with the control system is a direct indicator that an overhaul is required.

In such cases, a software audit and an inspection of wiring, sensors and parameters should be carried out.

6. Decline in overall machine performance

Increased fuel consumption, starting difficulties or reduced efficiency may sometimes be due not to the engine itself, but to a controller whose performance has deteriorated. This is often the case with older or poorly maintained systems.

NCG supports you

Implementing preventive maintenance not only helps to avoid these malfunctions, but also extends equipment life, secures installations and maintains a high level of performance. At Normandy Control Group, we support our customers in the maintenance, overhaul and replacement of their Woodward controllers, with services tailored to each model and configuration.

Our qualified technicians work in the workshop or on site to carry out the necessary checks, perform bench tests and restore controllers to perfect working order. Thanks to our expertise and in-depth knowledge of Woodward technologies, we can guarantee fast, rigorous service in line with industry standards.

Why do call on Normandy Control Group/NCG ?

When you choose Normandy Control Group, you choose a partner you can trust for the maintenance and repair of your industrial equipment. As an official Woodward and Parker Meggitt (vibro-meter) distributor in France and French-speaking Africa, including Algeria, Tunisia and Morocco, we offer recognized expertise in the field. We also have two workshops in France, in Le Havre and Marseille, as well as workshops in Côte d’Ivoire and Senegal.