Intervention on the regulation of a turbo-generator in the east of France

Discover how preventive maintenance of WOODWARD regulators helps prevent malfunctions in turbo-generators and ensures optimal operation of industrial machines.

On September 11, 2024, our team carried out a crucial troubleshooting intervention on the regulation of a turbo-generator. This machine, essential for the plant’s electricity production, was experiencing a critical speed regulation issue. Without a prompt intervention, a prolonged shutdown could have caused major production delays, jeopardizing the entire industrial process.

Indeed, the regulator, a PGG-EG 200 from Woodward, was no longer properly stabilizing the turbine speed. This malfunction directly impacted the plant’s ability to produce electricity efficiently. Aware of the stakes, the client reacted quickly by contacting us to avoid financial losses related to a production interruption.

Diagnosis of the issue with the turbo-generator regulation

On-site, our technician conducted a thorough visual inspection. Initially, nothing unusual was observed. However, upon starting the machine, he detected a rapid and significant drop in the oil level of the regulator. This regulator requires a sufficient amount of oil to operate optimally; otherwise, a lack of oil can lead to instabilities or failure.

A lack of oil can cause speed instabilities. It can even result in serious damage to the regulator if this issue is not addressed promptly.

- Rapide et efficace

- Intervention sur site

Intervention and regulation of the turbo-generator

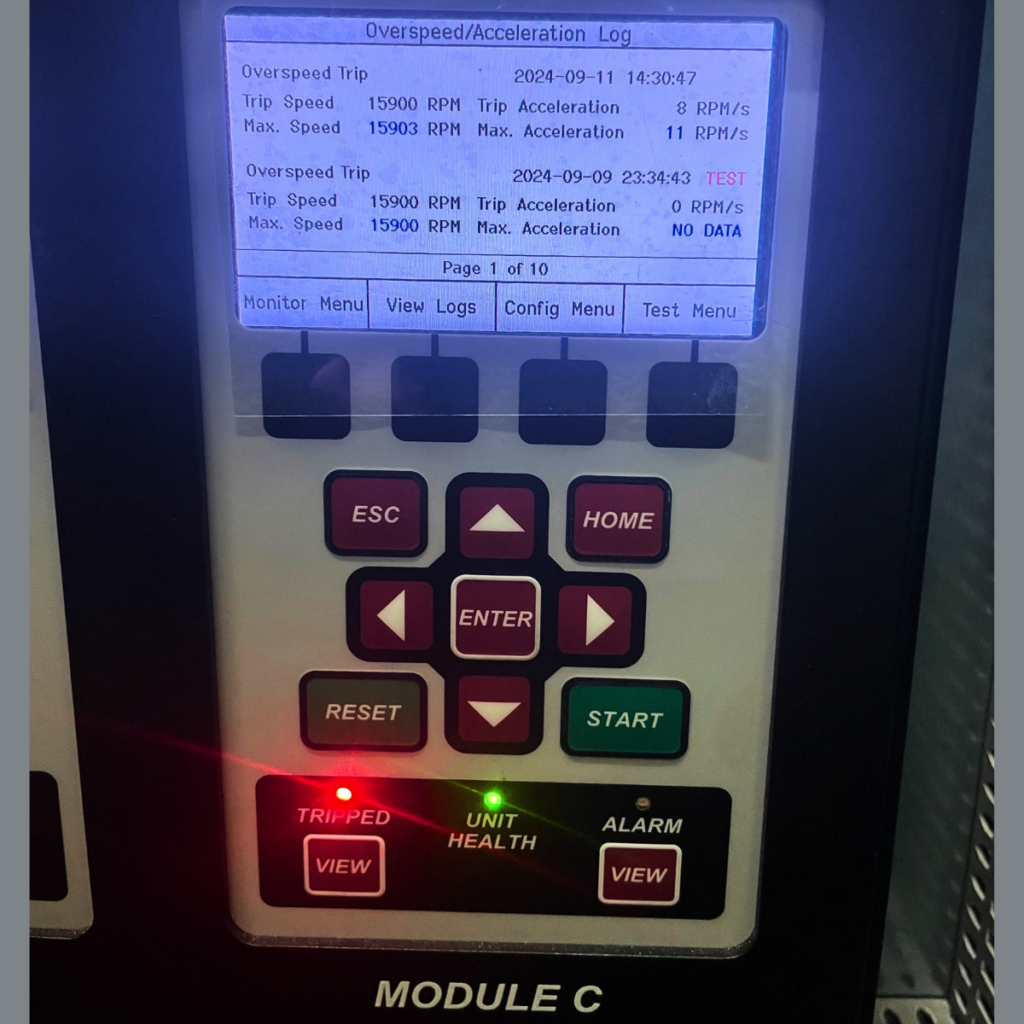

After identifying the cause of the malfunction, our technician quickly topped up the oil. The subsequent restart of the machine showed positive results. We conducted several tests to verify the machine’s performance.

The turbine reached a speed of 14,955 RPM without any issues. The coupling of the alternator to the grid was also validated. The load increase met expectations, as did the overspeed test.

Conclusion on the maintenance of turbo-generator regulation

This intervention allowed the plant to resume its operations normally, without any negative impact on its production campaign. All tests conducted confirm that the machine is now in perfect working condition. This incident highlights the importance of rigorous diagnosis and prompt intervention to minimize downtime and maintain optimal performance levels.

A big thank you to Steve Fleury for his expertise and professionalism, which made this intervention successful, as well as for his advice to the sugar factory teams to ensure the preventive maintenance of WOODWARD regulators.

Why call on Normandy Control Group?

Choosing Normandy Control Group means selecting a trusted partner for the maintenance and repair of your industrial equipment. As the official distributor of Woodward and Parker Meggitt in France and Francophone Africa, including Algeria, Tunisia, and Morocco, we offer recognized expertise in the field. With years of experience, our team of qualified technicians ensures rapid, precise diagnostics and effective interventions. Whether for complex regulations or precision adjustments, we are committed to maintaining the optimal performance of your machines. Thanks to our responsiveness, we reduce downtime and contribute to the continuity of your production, thereby ensuring the sustainability of your installations.

Faire appel à Normandy Control Group, c’est choisir un partenaire de confiance pour la maintenance et la réparation de vos équipements industriels. Distributeur officiel de Woodward et Parker Meggitt en France ainsi qu’en Afrique francophone, notamment en Algérie, Tunisie et Maroc, nous offrons une expertise reconnue dans le domaine.